The gang-saw TDG 2000 Series represents the best and most reliable solution for cutting particularly fractured or fragile marble blocks. It is a machine that works with the descent of the blade-holding frame, keeping the block fixed to the ground. The gang-saw has a cutting width of 2 mt.

Marble gangsaw TDG Series

TDG 2000 series

+ Reliability+ Cutting precision

+ Unique in its category

-

The blades-holding frame

The blades-holding frame is carefully studied and sized to ensure total stability and resistance to the load stresses caused by the tensioning of the blades.

The blades-holding frame moves by means of bronze sliders with hydrodynamic support that run on steel guides in an oil bath. An extremely simple and effective system, with very

low friction resistance, which does not require complex dynamic or hydraulic mechanisms and which needs very little maintenance. The tensioner is hydraulic and it is complete

with pump. -

Technology

Shaft, flywheel supports, connecting rod and its attachment to the blade-holding frame

Flywheel shaft and supports are adequately dimensioned to allow the use of a large flywheel. The connecting rod is made in welded structure and it is attached to the blades holding frame by means of four high-strength steel studs, which guarantee perfect coupling thanks to precision machining of both the plates and the attachment clamp, performed with numerical control machines. Thus welded connections are avoided, often a source of breakage due to fatigue over time.

-

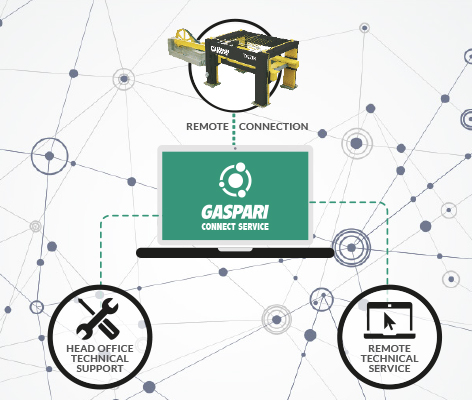

The electric board, “Industry 4.0” ready

The electrical/electronic system has been designed and built by adopting a FIELD BUS system, with consequent simplification of the wiring, guaranteeing a reduction in the possibility of failures and, “in case”, a more rapid and punctual search for them.

The electrical panel is designed according to the guidelines dictated by the canons of “Industry 4.0” and it is equipped with inverter. -

Details which make the difference

The Columns and the decent and ascent movements of the blade-holding frame

The columns are made of steel and, inside them, are positioned the screws for the vertical movement of the blade-holding frame, which occurs through bronze sliding blocks; the movement is driven by a brushless motor. The screws are protected from dust and water thanks to PVC bellows.