Our single wire machine is the right solution for squaring marble and granite blocks and to cut them into thick slabs.

Monowire

GMW 01

+ Accurate+ Reliable and Flexible

-

Tensioning system

Tensioning system

The tensioning of the wire is obtained by turning the arm on which one of the idle flywheels is fixed; the correct wire tension is controlled by adjusting the operating pressure of an oleopneumatic system that acts on the flywheel itself.

Downfeed Transmission System

The downward movement of the cut is obtained by vertically translating the sliders on the columns through linear guide systems composed of wheels and “C” shape guides. The use of this solution allows to obtain fluid motions even at very low down feed speeds together with high rigidity and sliding precision.

The vertical motion of the sliders is generated by a chain system driven by a brushless motor.

-

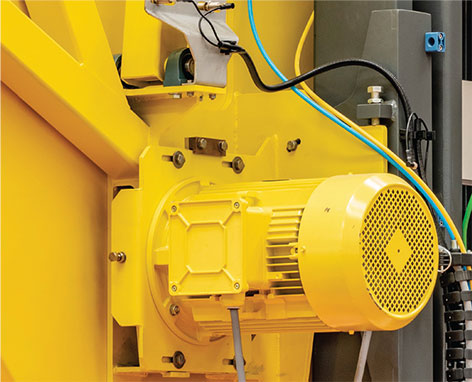

Main motor

Main motor

The wires rotate by means of four big flywheels with a diameter of 1200 mm each, of which only one is motorized.

The transmission of motion is obtained through trapezoidal belts driven by an asynchronous motor and driven by an inverter. -

Reliability and Precision

High reliability and cutting precision

The GMW 01 series models are designed taking advantage of the long experience gained by Gaspari in cutting granite and are the optimal machines for squaring blocks and cutting thicknesses (4 cm and more) with high precision. They are produced in different solutions to satisfy all requests: fixed single-wire machine, two-wire machine, composed of a fixed part and a mobile part on rails and a mobile single-wire machine on rails.